Optimizing Wine Production Pipelines

Introduction

In the wine industry, ensuring the quality and purity of the product throughout production is a critical task. One of the challenges wineries face is maintaining clean and efficient pipelines while transferring wine between tanks or through filtration and bottling systems. A solution increasingly adopted is the use of pigging systems wine.

These systems help wineries reduce product loss, improve hygiene, and streamline production processes, making them a vital tool in modern wine production.

Understanding Pigging Systems Wine

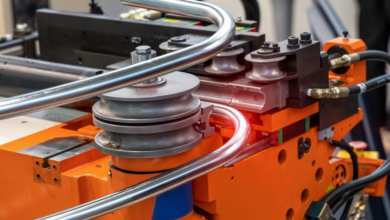

Pigging systems wine refers to the use of specially designed pigs within winery pipelines to move or clean wine efficiently. Unlike conventional pipeline cleaning methods, these systems allow for minimal product loss and maintain the wine’s quality, aroma, and color.

The pigs are inserted into pipelines to displace wine, clean residues, or move products from one process stage to another without exposing the wine to oxygen or contamination.

See also: The Creative Revolution Driven by Smart Technology

Benefits of Using Pigging Systems in Wineries

Reduced Product Loss

Wine left in pipelines during transfers or batch changes can result in significant loss. Pigging systems wine push nearly all remaining wine through the pipeline, ensuring maximum recovery.

Enhanced Sanitation

Wineries must maintain high hygiene standards. Pigging systems allow thorough cleaning of the lines, removing sediments, yeast residues, or other deposits without contaminating the wine.

Improved Efficiency

By reducing the need for manual cleaning and repeated transfers, pigging systems help speed up production processes, making operations more efficient.

Cost Savings

Minimizing product loss and streamlining cleaning procedures reduces waste and lowers operational costs, improving profitability.

Components of Pigging Systems Wine

A pigging system wine typically consists of:

- Launchers and Receivers: Devices installed at the start and end of the pipeline to insert and retrieve pigs.

- Sanitary Pigs: Constructed from food-grade materials to ensure they are gentle on wine while cleaning or transferring.

- Pipelines: Stainless steel or other food-safe piping suitable for wine production.

- Valves and Sensors: Control the pig’s movement and monitor flow to prevent damage to the wine.

Types of Pigs Used in Wine Production

Foam Pigs

Soft foam pigs are suitable for moving delicate wines without causing turbulence or oxygenation.

Rubber or Polyurethane Pigs

These provide a tighter seal against the pipeline, pushing out nearly all liquid while cleaning residue.

Sensor-Equipped Pigs

Advanced pigs can monitor their position and detect leftover product or line obstructions, improving efficiency and quality control.

Applications of Pigging Systems Wine

Line Transfers

During batch changes or when moving wine between fermentation, aging, or bottling tanks, pigs displace wine efficiently, preventing product wastage.

Cleaning and Maintenance

Pigging systems allow thorough cleaning of pipelines, removing sediment, yeast, or other residues to maintain high sanitary standards.

Preserving Wine Quality

By minimizing exposure to air and reducing pigging systems wine turbulence, pigging systems help preserve the wine’s aroma, taste, and color.

Integration with Existing Processes

Pigging systems can be integrated with filtration, bottling, and CIP (cleaning-in-place) processes to enhance operational efficiency.

Implementation Considerations

Wineries considering pigging systems wine should account for:

- Pipeline Design: Ensure smooth bends and proper diameters to allow pig movement without disruption.

- Material Compatibility: Use food-grade, sanitary materials for pigs and pipelines.

- Staff Training: Operators should be trained to handle pigs safely and efficiently.

- Regular Maintenance: Routine inspection of pigs and pipelines ensures optimal performance.

- Automation: Automated systems reduce manual labor and enhance consistency.

Best Practices

- Schedule Regular Pigging: Maintain consistent cleaning and product displacement.

- Monitor Pig Movement: Use sensors or flow indicators to track pigs and prevent blockages.

- Select Appropriate Pig Type: Choose pigs suited to wine type and pipeline configuration.

- Sanitize Pigs Thoroughly: Prevent cross-contamination between batches.

- Keep Records: Document pigging operations for quality control and regulatory compliance.

Challenges and Solutions

While pigging systems wine offer clear advantages, challenges include:

- Pipeline Complexity: Sharp bends or varying diameters may require specialized pigs.

- Initial Costs: Installation can be expensive, but long-term savings outweigh the investment.

- Training Requirements: Skilled operators are essential for safe and efficient operation.

- Sanitation Compliance: All system components must meet food-grade standards.

Future Trends in Wine Production

Wineries are increasingly adopting modern pigging systems wine with:

- Automation: Reducing manual intervention and enhancing consistency.

- Real-Time Monitoring: Sensors track pig location and detect residues for quality assurance.

- Customized Pig Designs: Tailored for specific wines and pipeline systems.

- Integration with CIP Systems: Combining pigging with cleaning-in-place for full sanitation.

These trends allow wineries to maintain high efficiency, improve product quality, and reduce operational costs.

Conclusion

Pigging systems wine play a crucial role in modern winery operations by ensuring efficient product transfer, minimizing waste, and maintaining high sanitary standards. Proper implementation enhances wine quality, preserves aroma and color, and reduces operational costs.

By investing in pigging systems wine and following best practices, wineries can optimize production processes while safeguarding the integrity of their products, ensuring both economic and qualitative benefits in their operations.