Siemens Servo Motors: Industrial Applications and Performance

Introduction to Siemens Servo Motors

Siemens servo motors have established themselves as vital components in modern industrial and automation systems. Renowned for precision, efficiency, and reliability, siemens servo motors provide accurate control of motion in a variety of applications. They are widely used in robotics, CNC machinery, automation lines, packaging equipment, and more. Understanding the design, benefits, and practical applications of siemens servo motors is essential for engineers, designers, and industry professionals seeking high-performance solutions.

Working Principle of Siemens Servo Motors

Siemens servo motors operate using a closed-loop control system. Each motor contains a rotor, stator, and a feedback device such as an encoder or resolver. The motor receives commands from a controller, which regulates voltage and current to achieve precise speed and rotation.

The feedback mechanism continuously monitors the motor’s position and performance, allowing the system to correct any deviations from the desired motion. This ensures accurate control of speed, torque, and position, even under varying load conditions. The closed-loop design enhances reliability, performance, and consistency in industrial applications.

Key Features of Siemens Servo Motors

Siemens servo motors offer several advantages over traditional motor systems:

- High Precision: Accurate control of position and speed makes them ideal for robotics, CNC machines, and automated assembly systems.

- Energy Efficiency: These motors convert electrical energy into mechanical energy effectively, reducing power consumption and operational costs.

- Compact Design: Small and lightweight construction allows easy integration into machines with limited space.

- High Torque Performance: Siemens servo motors provide strong torque in a compact size, suitable for demanding industrial tasks.

- Reliability: Constructed with high-quality materials, these motors offer long service life and consistent performance under harsh conditions.

Industrial Applications of Siemens Servo Motors

Siemens servo motors are widely used across multiple industries due to their precision, versatility, and reliability.

Automation and Robotics

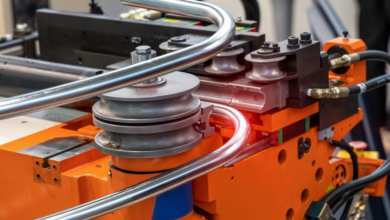

In industrial automation, siemens servo motors power robotic arms, conveyor systems, and automated production lines. Their precise motion control improves productivity, ensures repeatability, and enhances operational efficiency.

CNC Machinery

Computer numerical control (CNC) machines rely on siemens servo motors to control cutting, milling, and drilling operations accurately. This precision improves product quality, minimizes material waste, and enhances manufacturing efficiency.

Packaging Industry

siemens servo motors are essential in packaging machines for tasks such as labeling, filling, and sorting. Their accurate speed and position control enable high-speed operation without sacrificing precision.

Medical Equipment

Medical devices demand reliability and precision. Siemens servo motors are used in diagnostic machines, surgical instruments, and patient care systems. Their quiet operation and precise motion contribute to better performance and patient comfort.

See also: How Smart Home Technology Is Redefining Interior Design

Renewable Energy and Transportation

Siemens servo motors are increasingly applied in renewable energy systems, such as solar tracking systems and small wind turbines. In transportation, they power electric drives and control systems in vehicles, ensuring efficient and dependable operation.

Advantages of Siemens Servo Motors

Implementing siemens servo motors offers several advantages:

- Precision Control: Feedback systems provide accurate adjustments of speed, torque, and position.

- Energy Efficiency: Efficient conversion of electrical to mechanical energy lowers operational costs.

- Durability and Reliability: High-quality construction ensures long life and minimal downtime.

- Compact and Flexible: Their small size enables integration into complex machinery or limited spaces.

- High Torque Output: Capable of handling demanding industrial loads effectively.

Maintenance and Operational Considerations

Although siemens servo motors are robust, proper maintenance ensures optimal performance and longevity:

- Routine Inspection: Monitor for unusual noises, vibrations, or overheating to prevent unexpected failures.

- Clean Operating Environment: Dust and debris can reduce efficiency; keeping the area clean is essential.

- Stable Power Supply: Maintaining proper voltage and current prevents damage to the motor and controller.

- Temperature Management: Ensure adequate ventilation or cooling to avoid overheating and maintain efficiency.

Following these practices will maintain high performance and extend the operational lifespan of siemens servo motors.

Future Trends in Siemens Servo Motor Technology

Siemens servo motor technology continues to evolve to meet the demands of modern industrial applications. Emerging trends include:

- Smart Integration: IoT-enabled motors allow real-time monitoring, predictive maintenance, and energy optimization.

- Advanced Control Algorithms: Improved controllers provide smoother operation, higher efficiency, and precise motion.

- Miniaturization: Smaller designs enable integration into advanced machinery, medical devices, and robotics.

- Sustainable Applications: Energy-efficient designs support green manufacturing, renewable energy systems, and electric transportation.

These trends are expected to expand the applications of siemens servo motors while improving performance and energy efficiency.

Conclusion

Siemens servo motors play a crucial role in modern industrial and automation systems. They provide precise control, high torque, reliability, and energy efficiency, making them ideal for robotics, CNC machinery, packaging, medical devices, and renewable energy systems.

Understanding the design, features, and maintenance practices of siemens servo motors allows engineers and industry professionals to optimize performance, reduce operational costs, and achieve reliable, efficient, and precise operation. As technology advances, siemens servo motors will continue to be a cornerstone of innovation in industrial automation and high-performance machinery.