Top-Rated Titan Elite 3000 Sprayers Parts Explained

Introduction

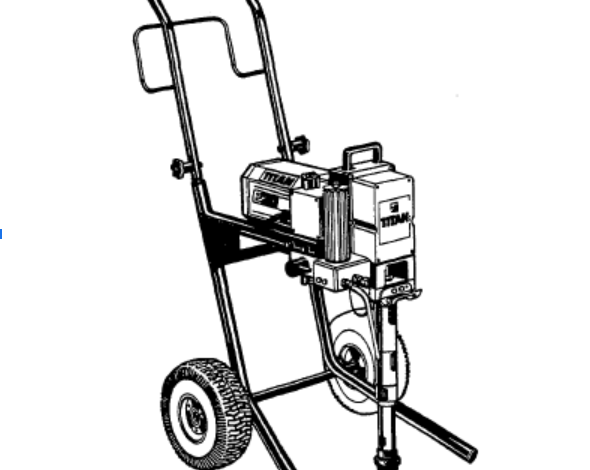

Alright, let me explain this in a simple, straight way—like we’re talking over the phone. If you’re using a Titan Elite 3000 paint sprayer, you already know it’s a serious machine built for professional-level performance. But here’s the thing most people overlook: the real power of this sprayer depends heavily on the quality and condition of its parts. Even the best sprayer won’t perform well if one small component is worn out or mismatched.

When people search for Titan Elite 3000 sprayers parts, they’re usually facing one of three issues—pressure loss, uneven spray patterns, or downtime due to part failure. That’s where understanding All Titan Parts becomes extremely important. Knowing what each part does helps you fix problems faster, avoid unnecessary replacements, and keep your sprayer running at peak efficiency.

In this guide, I’ll break down the top-rated Titan Elite 3000 sprayers parts, explain how they work, why they matter, and what makes them essential. No complicated jargon—just clear, practical explanations that actually help you make better decisions.

High-Performance Pump Assembly

The pump assembly is the heart of the Titan Elite 3000, and without it, nothing moves. This part is responsible for pulling paint from the container and pushing it through the system at consistent pressure. When the pump is working properly, you get smooth, even coverage without sputtering or pressure drops.

Over time, pump components experience wear due to constant pressure and material flow. Seals, pistons, and packings inside the pump can degrade, especially when spraying thicker coatings. That’s why replacing worn pump parts with genuine Titan Elite 3000 sprayers parts is critical for maintaining performance and preventing leaks.

A well-maintained pump assembly also improves efficiency. It reduces strain on the motor, ensures consistent spray output, and minimizes material waste. Professionals who rely on All Titan Parts know that keeping the pump in top condition directly impacts job quality and completion speed.

Durable Spray Gun and Trigger Components

The spray gun is where control meets precision. Every movement of the trigger regulates paint flow, making this component essential for accuracy and comfort. High-quality trigger assemblies ensure smooth operation and reduce hand fatigue during long spraying sessions.

Inside the spray gun, several small parts work together—needles, springs, filters, and seals. If even one of these wears out, you may experience dripping, inconsistent spray, or delayed shutoff. Replacing these components with correct Titan Elite 3000 sprayers parts restores proper control instantly.

Another benefit of well-maintained spray gun parts is safety. A responsive trigger reduces accidental overspray and material buildup. Professionals who regularly inspect and replace worn gun components using All Titan Parts enjoy better handling and cleaner results on every project.

Precision Spray Tips and Nozzles

Spray tips and nozzles determine how paint leaves the sprayer and hits the surface. The wrong tip size can cause overspray, clogging, or uneven coverage. That’s why Titan spray tips are engineered for precise fan patterns and controlled material flow.

With regular use, spray tips gradually wear down, increasing the orifice size and affecting spray quality. This often leads to wasted paint and rough finishes. Using correct Titan Elite 3000 sprayers parts ensures you maintain proper spray consistency and surface finish.

Professional painters often rotate and replace tips regularly as part of routine maintenance. High-quality tips from All Titan Parts help maintain efficiency, reduce rework, and deliver professional-grade results across different coating types.

Reliable Filters and Strainers

Filters might seem like small components, but they play a huge role in protecting your sprayer. Their job is to trap debris before it reaches sensitive internal parts like the pump or spray tip. Without effective filtration, clogs and internal damage become unavoidable.

The Titan Elite 3000 uses multiple filters at different stages—intake strainers, manifold filters, and gun filters. Each one has a specific purpose, and neglecting even one can lead to pressure issues or spray inconsistencies. Replacing them with correct Titan Elite 3000 sprayers parts keeps the system clean and efficient.

Clean filters also extend the life of other components. By preventing debris from circulating, All Titan Parts filtration components reduce wear, minimize downtime, and help maintain stable spray pressure throughout long jobs.

See also: How to Use a Vent Cleaning Kit Safely at Home

High-Pressure Hoses and Fittings

Hoses and fittings are responsible for safely transporting pressurized material from the sprayer to the gun. These components must handle high pressure without leaking, bursting, or restricting flow. Quality hoses ensure uninterrupted operation and consistent output.

Over time, hoses can develop internal wear, kinks, or weakened connections. Even small leaks can cause pressure loss and uneven spray patterns. Using compatible Titan Elite 3000 sprayers parts ensures a secure fit and reliable performance.

Strong fittings and durable hoses also improve job-site safety. Properly rated components from All Titan Parts reduce the risk of sudden failures, helping professionals work confidently in demanding environments.

Electric Motor and Drive Components

The motor is what powers the entire sprayer, converting electrical energy into mechanical force. A healthy motor ensures steady pressure, smooth operation, and reliable startup. Any issue here affects the whole system.

Drive components like gears and couplings transfer motor power to the pump. Wear in these parts can cause vibration, noise, or inconsistent pressure. Replacing worn components with correct Titan Elite 3000 sprayers parts restores balance and efficiency.

Maintaining motor-related components also improves longevity. Professionals who rely on All Titan Parts understand that a well-supported motor reduces breakdowns and keeps the sprayer ready for continuous use.

Control Board and Pressure Regulation Parts

The control board manages pressure settings and overall system operation. It allows users to adjust output based on material type and job requirements. Accurate pressure control is essential for achieving professional finishes.

Pressure regulation components like sensors and valves ensure consistent output during spraying. If these parts malfunction, pressure fluctuations can occur, leading to poor results. Using correct Titan Elite 3000 sprayers parts ensures stable and predictable performance.

Reliable control components also protect the sprayer from overload. By maintaining proper pressure levels, All Titan Parts help prevent excessive wear and unexpected shutdowns during critical jobs.

Conclusion

Let me put it simply—your Titan Elite 3000 is only as good as the parts inside it. Understanding and maintaining Titan Elite 3000 sprayers parts isn’t just about fixing problems; it’s about preventing them before they happen. Every component, from the pump to the smallest filter, plays a role in performance, safety, and efficiency.

Using high-quality All Titan Parts ensures compatibility, durability, and consistent results. It saves time on the job, reduces material waste, and keeps your sprayer running smoothly when you need it most. Professionals who invest in proper parts always see better long-term value.

If you treat your sprayer like a system instead of a single machine, you’ll get more reliable performance, fewer breakdowns, and cleaner finishes on every project. That’s the real advantage of understanding your equipment inside and out.