Modern Techniques in Metal Bending

Introduction to Industrial Metal Forming

In modern manufacturing, precision and efficiency are essential for producing high-quality metal components. Metal bending has evolved significantly, with specialized machines improving accuracy and reducing labor. These developments allow industries to meet higher production demands while maintaining consistency and structural integrity in their products.

How Advanced Machines Operate

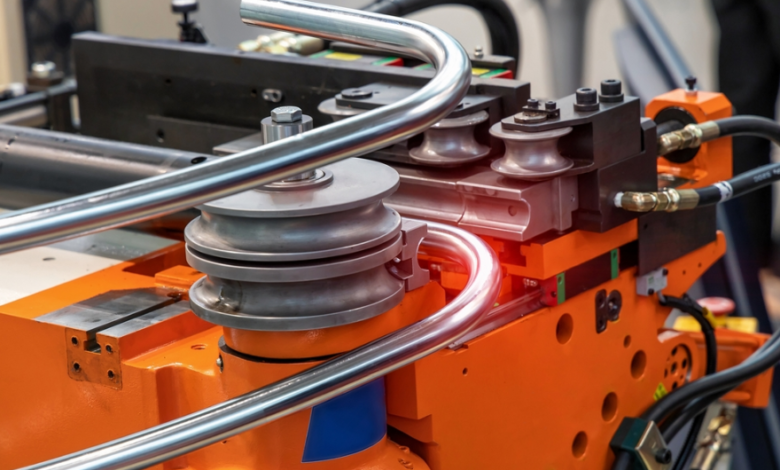

Modern bending machines are designed to handle a variety of materials and thicknesses. By using controlled force and precise alignment, they shape metal sheets accurately according to required specifications. Automation in these machines allows operators to input exact parameters, reducing human error and improving repeatability.

The integration of computer controls and hydraulic systems ensures that each operation is consistent. Operators can program specific bend angles and sequences, which speeds up production and minimizes material waste.

Types of Metal Bending Machines

Metal bending technology encompasses several types of machines, each suited for different industrial applications:

Mechanical Presses: Operate through levers and mechanical force, suitable for lighter tasks.

Hydraulic Systems: Use fluid pressure to bend heavier metals, allowing for complex shapes and consistent results.

Computer-Controlled Machines: Combine automation and precision, supporting intricate designs with minimal supervision.

Hydraulic systems in particular provide smooth operation and control over bending speed and pressure, which is critical for materials prone to cracking or deformation.

Advantages in Industrial Applications

Using modern bending machines provides significant advantages in manufacturing:

Precision and Accuracy: Ensures bends meet exact specifications.

Increased Efficiency: Reduces manual labor and shortens production cycles.

Material Versatility: Can handle metals ranging from soft aluminum to thick steel plates.

Operational Reliability: Maintains consistent performance over long production runs.

These advantages translate to cost savings, improved product quality, and higher production output.

See also: How Smart Home Technology Is Redefining Interior Design

Selecting the Appropriate Machine

Choosing the right machine requires careful consideration of several factors:

Material Type: Different metals require specific bending approaches.

Production Requirements: High-volume operations need machines capable of sustained performance.

Precision Needs: Industries such as automotive and aerospace demand minimal deviation in bends.

Maintenance and Support: Machines with accessible service options reduce downtime and prolong operational life.

Selecting the proper machine ensures efficiency, reliability, and safety throughout the production process.

Integration with Modern Manufacturing Systems

Many metal bending machines today are compatible with factory automation systems. This connectivity allows for real-time monitoring, predictive maintenance, and workflow optimization. Operators can track performance data and adjust processes to improve efficiency. Integrating machines into a larger automated system also supports the development of smart factories and advanced manufacturing techniques.

Safety and Environmental Considerations

Safety in industrial operations is paramount. Modern machines include protective features such as emergency stops, safety shields, and automated shutoffs. Advanced solutions like the

hydraulic press brake

offer enhanced safety controls, precision, and energy efficiency. These mechanisms help prevent accidents and injuries during operation while aligning production with sustainable practices.

Training and Skilled Operation

Even with automated systems, skilled operators are crucial. Proper training ensures personnel can program, operate, and troubleshoot machines effectively. Combining human expertise with advanced technology maximizes productivity, reduces errors, and enhances product quality.

Future Trends in Metal Bending

Looking ahead, the incorporation of artificial intelligence and machine learning into bending machines is likely to further improve precision and efficiency. Machines could automatically adjust parameters based on material behavior and previous tasks. Additionally, innovations in lightweight, energy-efficient designs will expand the range of applications for modern metal bending technology.

Conclusion

Advancements in metal bending technology have transformed industrial manufacturing, providing precision, efficiency, and versatility. Understanding the capabilities and advantages of these machines allows manufacturers to enhance productivity, ensure high-quality output, and meet growing industrial demands. As technology continues to evolve, these machines will remain integral to modern fabrication processes.