Advancing Metal Fabrication with Modern Technology

Introduction

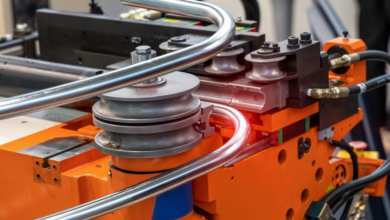

The field of metal fabrication has seen remarkable advancements over the past few decades. Modern machinery allows manufacturers to achieve higher precision, better efficiency, and increased consistency. Among the most advanced tools available today, certain multi-axis press brakes have redefined how complex bending tasks are handled in industrial settings. These machines are capable of performing intricate bends with minimal manual intervention, making them ideal for industries demanding precision and high productivity.

Understanding Advanced Press Brake Technology

Press brakes have evolved far beyond simple mechanical machines. Multi-axis machines now integrate advanced controls and robust designs to meet the challenges of modern production. An 8 axis press brake represents one of the most sophisticated developments in this category, combining precision engineering with advanced automation.

Key features include:

- Multiple independent axes for fine-tuned control of sheet positioning

- CNC integration for programming complex bending sequences

- High structural rigidity to maintain accuracy and reduce vibration

- Versatile drive systems, including hydraulic, electric, or hybrid options

- Operator safety mechanisms such as light curtains, emergency stops, and protective barriers

These features collectively enhance productivity and ensure consistent high-quality results.

Advantages Over Conventional Machines

Modern multi-axis machines offer several advantages compared to traditional press brakes:

- Improved Precision: Each axis can be controlled independently, enabling exact bend angles and minimal deviation.

- Efficiency Gains: Automated control reduces setup time and streamlines production cycles.

- Material Versatility: These machines can handle different metals, thicknesses, and complex geometries.

- Consistency Across Batches: CNC programming ensures uniform results, even for large-scale production.

- Reduced Dependence on Skilled Labor: Automation reduces reliance on operator expertise alone.

These improvements make multi-axis press brakes a valuable investment for modern fabrication facilities.

Applications in Various Industries

The capabilities of advanced press brakes extend across multiple sectors:

- Automotive: Fabricating panels, brackets, and custom components.

- Aerospace: Producing lightweight, precisely bent parts for aircraft structures.

- Construction: Manufacturing structural supports, architectural panels, and metal components.

- Electrical Equipment: Creating enclosures, housings, and control panels.

- Prototype and Custom Work: Supporting innovation through precise small-batch production.

The flexibility of machines like the 8 axis press brake allows them to meet the demands of highly varied industrial applications.

See also: How Smart Home Technology Is Redefining Interior Design

The Role of Multi-Axis Control

The true strength of an 8 axis press brake lies in its multi-axis capability:

- Back Gauge Positioning: Multiple axes ensure accurate placement of sheets for precise bends.

- Tool Alignment: Independent axis control allows for exact punch and die positioning.

- Complex Operations: Machines can perform multi-step bends without repositioning the material.

- Real-Time Adjustments: CNC systems monitor and adjust movement to maintain precision.

This combination of features results in higher accuracy, reduced scrap, and more efficient workflows.

Choosing the Right Press Brake

Selecting the appropriate press brake involves careful consideration of several factors:

- Axis Requirements: Match the number of axes to the complexity of tasks.

- Drive Technology: Hydraulic, electric, or hybrid systems affect performance and energy efficiency.

- Software Capability: Advanced CNC systems simplify programming and reduce errors.

- Support Services: Manufacturer training, support, and maintenance are critical for long-term success.

- Build Quality: Durable components and robust frames ensure reliability and longevity.

Making an informed decision ensures optimal performance, efficiency, and return on investment.

Maintenance and Longevity

Maintaining advanced machines is essential for long-term performance:

- Regular Inspections: Monitor alignment, hydraulic systems, and structural integrity.

- Lubrication: Keep moving parts in optimal condition to reduce wear.

- Software Updates: Ensure CNC systems are current to avoid operational errors.

- Skilled Operation: Trained operators help prevent misuse and prolong machine life.

Routine maintenance ensures consistent quality and reduces downtime.

Economic and Productivity Benefits

Investing in high-end press brakes provides measurable financial advantages:

- Reduced Waste: Accurate bends minimize scrap material.

- Faster Production: Automated operations shorten cycle times.

- Lower Labor Costs: Automation reduces dependency on manual input.

- Long-Term Reliability: High-quality machines reduce repair costs and unplanned downtime.

These benefits translate into improved productivity and a lower cost per unit.

Future Trends in Press Brake Technology

Looking forward, press brake technology continues to evolve with emerging trends:

- Smart Integration: IoT-enabled machines allow real-time monitoring and data collection.

- Predictive Maintenance: Sensors can detect potential issues before they cause failures.

- Energy Efficiency: Electric and hybrid systems reduce energy use and environmental impact.

- Automation: Robotic loading and unloading increase speed, safety, and consistency.

The integration of these innovations will continue to push the boundaries of metal fabrication.

Conclusion

Advanced press brakes, such as the 8 axis press brake, have transformed the metal fabrication industry. They combine precision, flexibility, and automation to handle complex tasks efficiently and consistently. With careful selection, proper maintenance, and skilled operation, these machines are invaluable assets in producing high-quality components for diverse industrial applications. As technology continues to progress, these machines will play an increasingly central role in modern manufacturing.