Understanding the Role of breather valve Systems in Modern Manufacturing

Introduction to the Importance of Controlled Pressure Management

In any industrial environment, maintaining safe and stable internal pressure is essential for smooth operations. Whether it is chemical storage, fuel handling, electronics production, or large-scale processing, pressure fluctuations can lead to contamination, damage, or operational failure. Among the devices used to manage this challenge, the breather valve plays an important role in preserving equipment integrity and ensuring consistent performance.

Although commonly associated with fluid systems and chemical storage tanks, this component also connects indirectly with industries like PCBA manufacturing. In such environments, sensitive equipment, assembly materials, and electronic components require controlled atmospheric exposure. The proper use of ventilation and controlled pressure release helps maintain ideal working conditions during the production process.

What a Breather Valve Is and How It Works

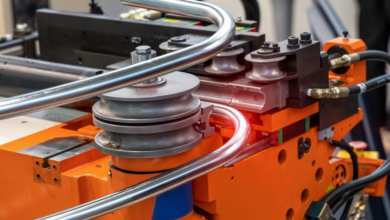

A breather valve is a mechanical safety device used to regulate pressure within a closed system. When pressure rises above the allowed limit, the valve opens to release excess gas or vapor. At the same time, when negative pressure begins to build, the valve allows air to enter so the container or system does not collapse inward.

This simple mechanism prevents major hazards such as structural damage, leakage, and contamination. The device operates automatically, requiring no external controls or manual adjustments once installed.

Applications Across Multiple Industries

Breather valves are widely used in storage tanks, pipelines, fuel reservoirs, chemical containers, and ventilation systems. Their ability to maintain stable pressure levels makes them valuable across numerous industries.

In electronics and PCBA manufacturing, controlled exposure to air is important to protect sensitive components from moisture and debris. While electronic production environments do not use the exact same Breather Valves technology as large industrial tanks, similar principles apply. Controlled pressure exchange and airflow management are essential to ensure that components remain free from dust, and assembly processes remain consistent.

See also: How Smart Home Technology Is Redefining Interior Design

Why Pressure Control Matters for Electronics Production

The PCBA manufacturing industry requires high precision. Tiny electronic parts, solder joints, and micro-circuits can be damaged by environmental changes that seem insignificant. Pressure imbalance can lead to issues such as unexpected moisture accumulation, airflow obstruction, or even chemical buildup in storage areas.

By understanding how pressure management devices work, manufacturers can design better storage units, material containers, and sealed production systems. Concepts used in breather valve engineering are applied to humidity-controlled cabinets, chemical storage for solder pastes, and protective containers used in electronics plants.

Different Types of Breather Valves and Their Functions

There are several variations of the breather valve, each created for different environments. Two of the most common types are pressure-only valves and vacuum-only valves. However, many industries prefer combination valves because they handle both functions in a single device.

Spring-loaded models provide precise pressure control, while weight-loaded versions are used in large storage systems that require slow and steady pressure adjustments. Flame arrestor breather valves provide additional safety in environments where combustible vapors may be present.

Advantages of Using a Breather Valve in Industrial Settings

Using a breather valve offers multiple advantages that improve safety and operational efficiency.

One of the key benefits is protection from excessive internal pressure, which can damage equipment or cause leaks. The device also reduces the risk of vacuum collapse, protecting the structural integrity of tanks and other enclosed systems.

Another advantage is that these valves reduce the escape of harmful vapors, which helps maintain a healthier working environment. Many designs also prevent dust and contaminants from entering the system during pressure intake, reducing corrosion and contamination risks.

Significance of High-Quality Components and Precision Engineering

Manufacturing high-performing pressure control devices requires precise engineering. Small defects can lead to serious failures, so every part must be carefully designed and tested.

In the PCBA industry, quality control is equally crucial. Just as a breather valve must operate flawlessly under varying pressure levels, printed circuit board assemblies must function perfectly under electrical and mechanical stress. Both fields rely on accuracy, durability, and strict inspection standards to ensure the highest level of performance.

Maintenance Practices for Long-Term Reliability

Regular inspection and maintenance of breather valves ensures long life and consistent function. Maintenance teams check for dirt accumulation, corrosion, and mechanical wear. Cleaning or replacing the filter elements is important to ensure unrestricted airflow.

Calibration should also be verified periodically to ensure that the valve opens and closes at the correct pressure levels. A poorly maintained device may not respond to pressure changes, which can pose safety risks.

How Technology Is Improving Modern Valve Designs

Technological advancements allow manufacturers to create more reliable and efficient valve systems. Modern designs offer features such as corrosion-resistant coatings, modular construction, and more responsive mechanical components.

Some industries are experimenting with smart sensing technology, where pressure monitoring systems detect and report issues in real time. Although these innovations are more common in advanced industrial applications, similar monitoring techniques are now being integrated into PCBA environments to track temperature, humidity, and environmental conditions.

Selecting the Right Valve for Industrial Use

Choosing the correct breather valve requires understanding system requirements such as pressure range, material compatibility, environmental conditions, and safety regulations. Each application needs a design that fits the operating environment.

For electronics-related environments, emphasis should be placed on systems that protect sensitive materials from contamination and moisture. Proper ventilation solutions contribute to stable manufacturing conditions, resulting in higher production quality.

Connection Between Pressure Control and Product Quality

Stable pressure and clean airflow are foundational requirements for high-quality industrial production. Whether storing chemicals or assembling printed circuit boards, maintaining environmental stability ensures consistent results.

A breather valve itself may not be used directly in PCBA assembly lines, but the principles behind its design influence modern environmental control systems. Ensuring safe air exchange, preventing moisture buildup, and controlling internal pressure all contribute to better product reliability.

Conclusion: The Ongoing Importance of Reliable Pressure Regulation

Pressure fluctuations can create serious challenges in manufacturing environments. The breather valve remains one of the simplest yet most effective solutions for managing these fluctuations safely. Its role in protecting equipment, controlling airflow, and preventing contamination makes it essential across many industries.

As technology continues to evolve, pressure control systems will grow even more advanced, offering better safety and improved efficiency. Understanding how these devices operate helps engineers and manufacturers in every sector, including PCBA production, create safer, cleaner, and more reliable working environments.