Achieving Precision in Sheet Metal Bending

Introduction

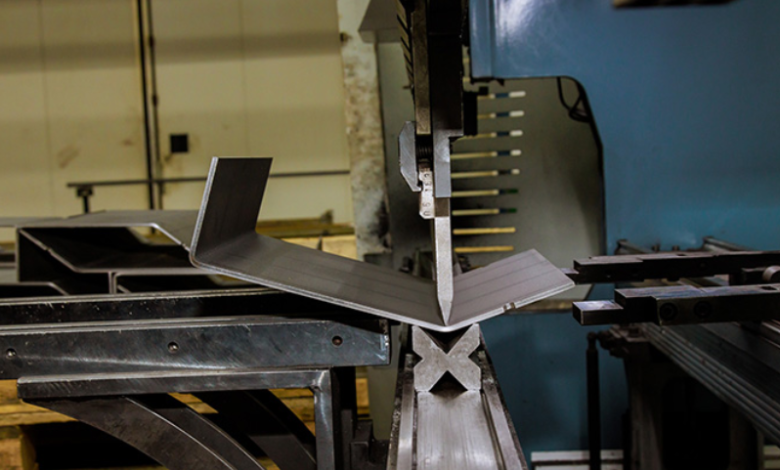

In modern metal fabrication, achieving high precision and consistency is essential for quality production. Among the vital components that ensure accurate bending results is the back gauge for press brake. This device plays a crucial role in positioning sheet metal correctly before bending, ensuring each piece meets design specifications. With advancements in automation and CNC technology, this component has become a cornerstone of efficient and accurate sheet metal processing.

Understanding the Function of a Back Gauge

The back gauge for press brake is a mechanical and electronic system designed to stop and position sheet metal at a specific point before it is bent. It determines the distance between the edge of the sheet and the bending line, ensuring precise and repeatable operations.

Operators can set the desired dimensions through a control panel or CNC system, which then moves the back gauge automatically into position. This ensures accuracy without relying on manual measurements, significantly reducing human error and increasing production speed.

Key Components of the System

A modern back gauge system consists of several integrated parts that work together to deliver precise positioning.

1. Gauge Fingers

Gauge fingers are adjustable stops that make contact with the metal sheet. They are essential for maintaining consistent positioning during each bend, ensuring all parts have identical dimensions.

2. Drive Mechanism

The drive mechanism is responsible for moving the gauge fingers along the axis. Depending on the machine’s design, it may use mechanical, hydraulic, or servo-electric systems. Servo drives are especially popular due to their accuracy, speed, and low maintenance requirements.

3. Control Unit

This is where the operator inputs the required parameters for bending. In CNC machines, the control unit can store multiple programs, automatically adjusting the back gauge for each bend in a sequence.

4. Linear Guides and Sensors

Linear guides ensure smooth and accurate movement of the gauge fingers. Sensors and linear encoders monitor positions in real-time, ensuring deviations are immediately corrected for consistent precision.

See also: The Creative Revolution Driven by Smart Technology

Variants of Back Gauges in the Industry

Different types of back gauges are used in press brakes depending on the level of automation and production needs.

1. Manual Back Gauge

A manual version requires the operator to set the back gauge for press brake position using hand controls. It is simple and affordable, suitable for small workshops or custom jobs that don’t require automation.

2. Motorized Back Gauge

This system uses electric motors to adjust the position of the gauge fingers. It offers faster setup times and greater consistency than manual systems, making it ideal for medium-scale production.

3. CNC-Controlled Back Gauge

CNC models represent the highest level of automation. They can store and recall complex bending sequences, automatically adjusting the back gauge position between operations. This feature significantly enhances efficiency in high-volume production lines.

Benefits of Using a Back Gauge in Fabrication

Integrating a high-quality back gauge for press brake into manufacturing processes offers several key advantages.

1. Superior Accuracy

Automation ensures precise and repeatable sheet positioning for every bend, resulting in consistent dimensions and fewer defective parts.

2. Reduced Setup Time

By automating adjustments, operators can quickly switch between different bending programs, improving workflow efficiency and minimizing downtime.

3. Enhanced Productivity

The system’s speed and precision allow manufacturers to handle more work in less time while maintaining product quality.

4. Material and Cost Savings

Accurate positioning minimizes errors and waste, helping to reduce material costs and improve profitability.

5. Improved Safety

Automated systems limit the need for manual intervention near the bending zone, enhancing operator safety during production.

Applications in Metal Fabrication

The back gauge for press brake is an essential component across multiple sectors that rely on precise sheet metal bending.

- Automotive industry: Used in manufacturing car body panels, chassis parts, and brackets.

- Aerospace sector: Helps in forming lightweight yet precise aircraft components.

- Electronics and appliances: Ensures accurate bending for enclosures, brackets, and frames.

- Construction industry: Supports the fabrication of beams, cladding, and structural components.

Each of these industries demands uniform and reliable bends that can only be achieved with advanced positioning systems.

Maintenance and Calibration

For optimal performance, regular maintenance and calibration of the back gauge are essential. Accumulated dust, oil, or debris can interfere with movement and accuracy. Recommended maintenance practices include:

- Cleaning linear guides and gauge fingers regularly.

- Checking for mechanical wear and tightening bolts if necessary.

- Inspecting sensors, scales, and cables for damage.

- Performing calibration checks to ensure positional accuracy.

Scheduled preventive maintenance extends the machine’s lifespan and reduces the risk of unplanned downtime.

Technological Advancements and CNC Integration

CNC technology has completely transformed how press brakes operate. The integration of CNC systems with back gauges allows automatic control of multiple bending steps. Operators can program complex sequences and store them for future use, significantly enhancing efficiency.

Advanced CNC models also connect with CAD/CAM software, enabling digital designs to be directly converted into bending instructions. This eliminates manual data entry, reduces setup errors, and allows for seamless workflow from design to production.

The Future of Back Gauge Systems

With the rapid advancement of automation and smart manufacturing, the back gauge for press brake continues to evolve. Modern innovations are introducing intelligent systems that can adapt and self-adjust based on material type and thickness. Future trends include:

- IoT connectivity: Enables real-time data monitoring and predictive maintenance.

- AI optimization: Systems capable of learning from production data to enhance accuracy and efficiency.

- Touchscreen interfaces: Simplify user interaction and setup processes.

- Full automation: Integration with robotic arms for continuous, unmanned production.

These developments are driving the industry toward higher precision, speed, and sustainability.

Conclusion

The back gauge for press brake plays an indispensable role in ensuring accuracy, efficiency, and consistency in sheet metal fabrication. By automating positioning and reducing human error, it enables manufacturers to produce high-quality parts with minimal waste and downtime.

As technology progresses, these systems will continue to evolve, offering even greater levels of control, integration, and intelligence. For any workshop or manufacturing facility focused on precision and productivity, investing in a reliable back gauge system is a strategic move toward future-ready fabrication.